On-Site Equipment & Inventory Management: Keeping Long Island’s Operations Running Without Downtime

When a single failed hose can halt production or sideline a fleet, being prepared isn’t optional — it’s essential. Long Island Hose provides customized on-site inventory programs that help Long Island businesses stay stocked, efficient, and ready to work. Our goal isn’t to sell you more parts — it’s to help your operation run smoother, save time, and stay in control.

Real-World Reliability — Case Study: Fleet Maintenance Facility, Bohemia NY

A local fleet maintenance company servicing over 40 trucks faced constant downtime waiting on fittings and hoses from third-party suppliers. Each lost hour meant idle mechanics and late

deliveries.

After partnering with Long Island Hose, the shop installed an on-site inventory station stocked with its most used ½-inch and ¾-inch hydraulic assemblies and adapters. Within two months:

- Parts-related downtime dropped by 65%

- The shop reduced local supplier runs from daily to once a week

- Labor savings exceeded $800 per month simply by avoiding per-crimp fees

Now, their mechanics assemble what they need immediately — keeping vehicles on the road and operations on schedule.

Common Questions About On-Site Inventory Management

What exactly is an on-site inventory program?

How does it save time?

What types of businesses benefit most?

- Construction & excavation companies

- Fleet & equipment repair shops

- Marine & dock facilities

- Industrial & manufacturing operations

Do I need to buy equipment?

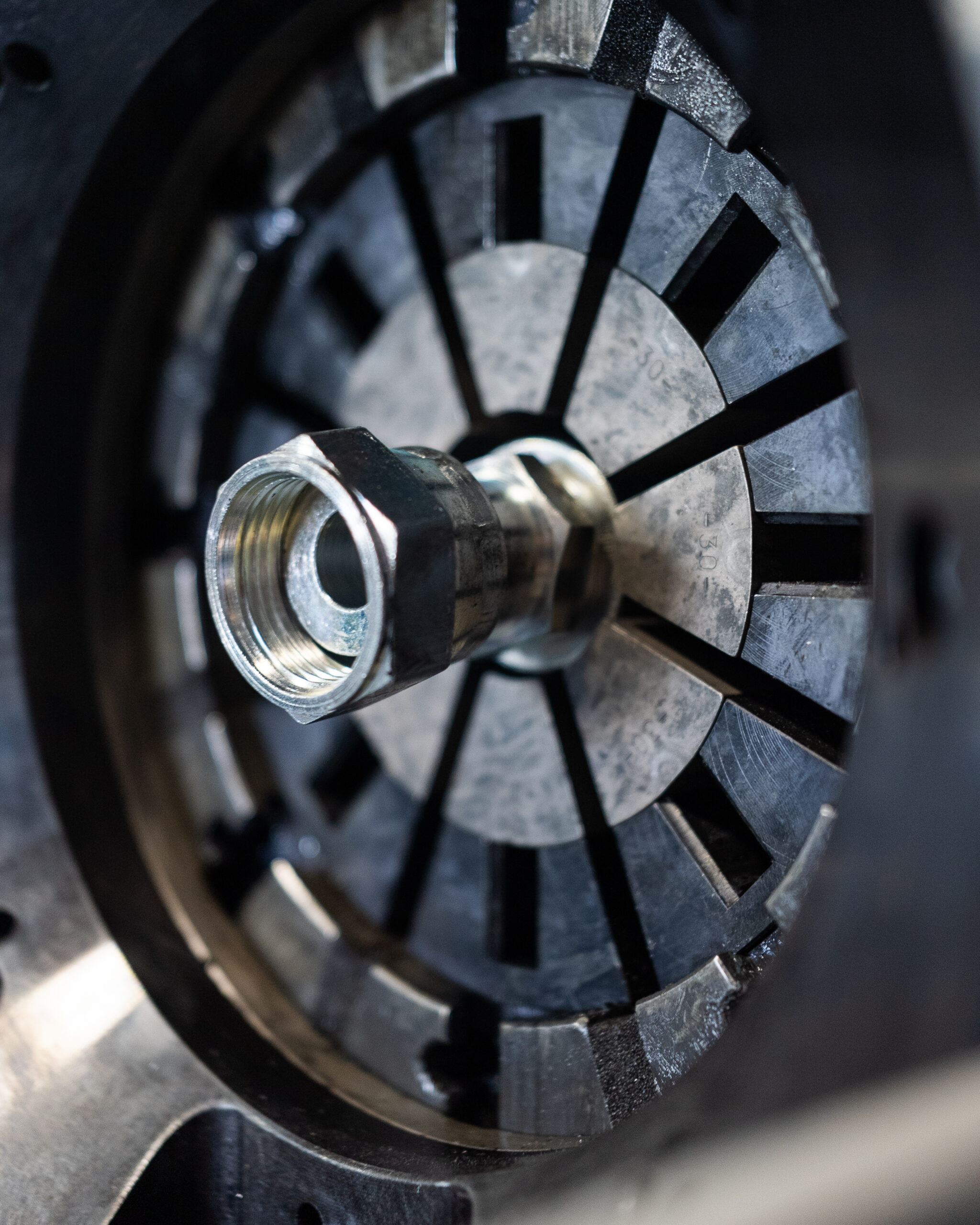

Not necessarily. Some programs include crimping machines (such as the MRB137 or GoldenCrimp 420 EVO) at no additional cost depending on your plan.

Who manages my inventory?

Every client has a dedicated Long Island Hose representative who monitors your stock levels and coordinates restocking deliveries. You can also manage it yourself — completely flexible.

How the Program Works — Step by Step

On-Site Evaluation

We visit your facility to assess hose usage, repair frequency, and storage options.

Custom Setup

We design and install the right system for your space, complete with labeled bins, hose racks, and organized fittings.

Team Training

Your staff receives a hands-on training session covering proper assembly, crimping, and identification charts.

Delivery & Restocking

We deliver new stock as needed, ensuring you never run out.

Ongoing Support

You’ll have a dedicated salesperson who manages supply, audits usage, and suggests improvements as your business grows.

Case Study — Construction Equipment Yard, Riverhead NY

A construction firm with multiple crews was losing an average of 2 hours per job when hoses failed unexpectedly. After implementing Long Island Hose’s on-site inventory system and scheduled delivery program:

- Downtime per job dropped from 2 hours to 30 minutes

- Technicians were trained to fabricate simple hoses in-house

- Replacement part costs went down due to bulk pricing agreements

Their foreman described the program as “like having a mini-hose shop in the yard.

Why It Works for Long Island Businesses

No Minimums to Start – programs scale with your workload.

Scheduled Deliveries – we handle replenishment automatically.

Hands-On Training – confidence and efficiency for your team.

Proven ROI – every hour saved in downtime is profit back to your operation.

Built for uptime. Trusted by the businesses that keep Long Island moving.